History:

Bill Smith coined the term 6 Sigma & is called "Father of 6 Sigma"

Mikel Harry coined terms - Black Belt & Green Belt

Normal Curve - Carl Friedrich Gauss

1920 - Control Charts - Walter Shewhart

1935 - Design of Experiments - Ronald Fisher

1940 - FMEA - Failure Modes & Effect Analysis - US armed Forces

1940 - MSA - Measurement Systems Analysis - AIAG Automotive Industry Action Group

1960s - Ishikawa Diagrams - Kaoru Ishikawa

1960s - Six Thinking Hats - Dr. Edward de Bono

1960s - Pugh Method or Decision-matrix method - Stuart Pugh

1963 - Delphi Technique - Dalkey & Helmerr - Rand Corporation

1977 - Box Plot - John Tukey

Lean Tools:

5s - Sort, Set in Order, Shine, Standardize, Sustain

Andon

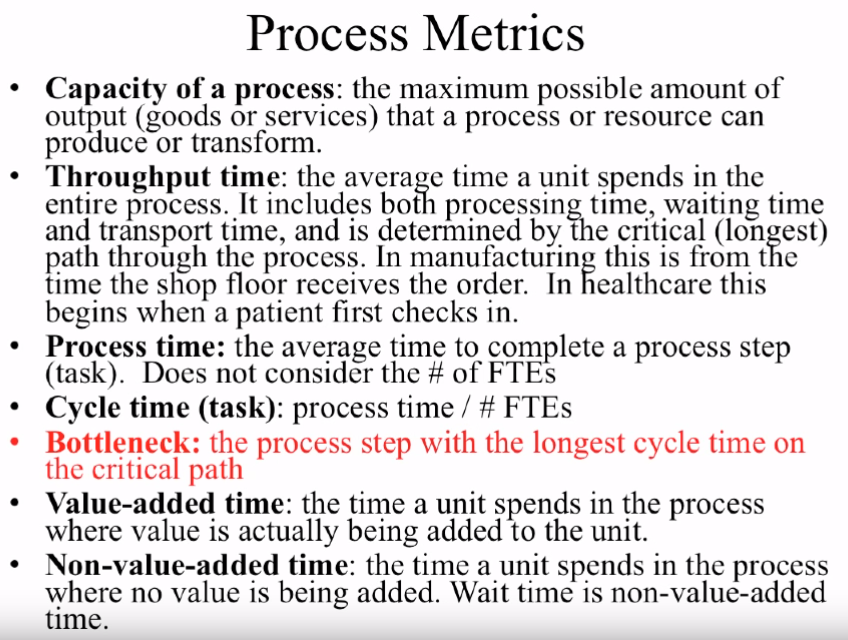

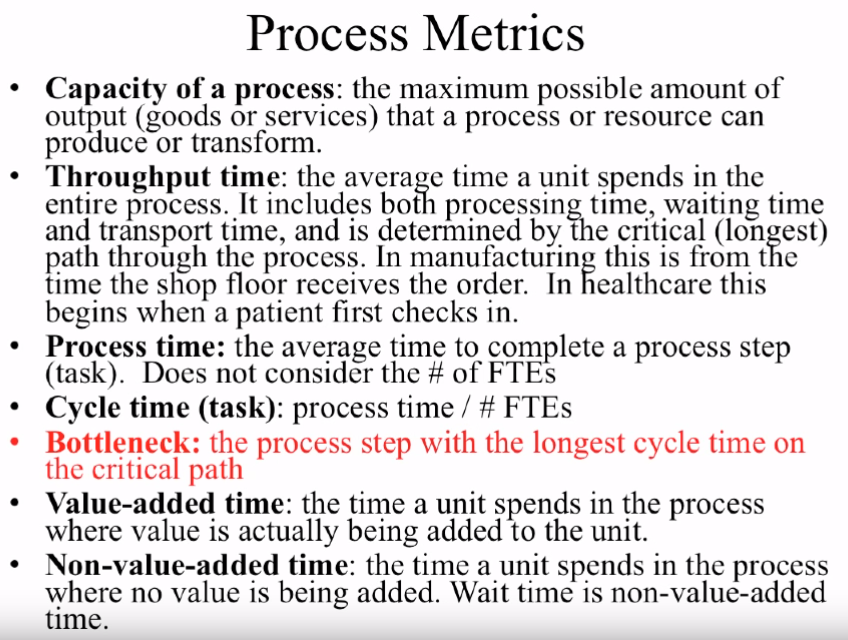

Bottleneck Analysis

Continuous Flow

DMAIC (Define, Measure, Analyze, Improve, Control)

Gemba (The Real Place)

Heijunka (Level Scheduling)

Hoshin Kanri (Policy Deployment)

Jidoka (Automation)

Just-In-Time (JIT)

Kaizen (Continuous Improvement)

Kanban (Pull System)

KPIs (Key Performance Indicators)

Muda (Waste)

Overall Equipment Effectiveness (OEE) - Availability, Performance, Quality

PDCA (Plan, Do, Check, Act)

Poka-Yoke (Error Proffing)

Root Cause Analysis

Single-Minute Exchange of Dies (SMED)

Six Big Losses

SMART Goals

Standardization Work

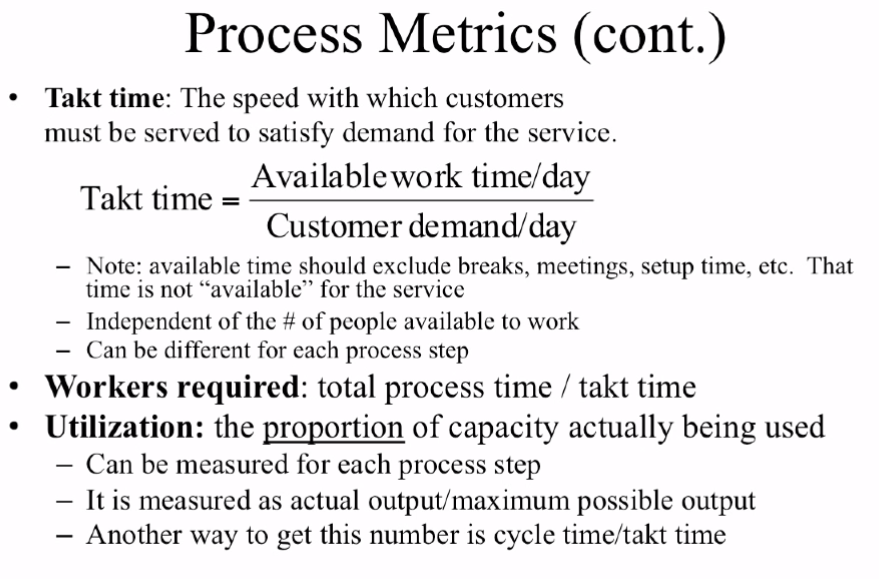

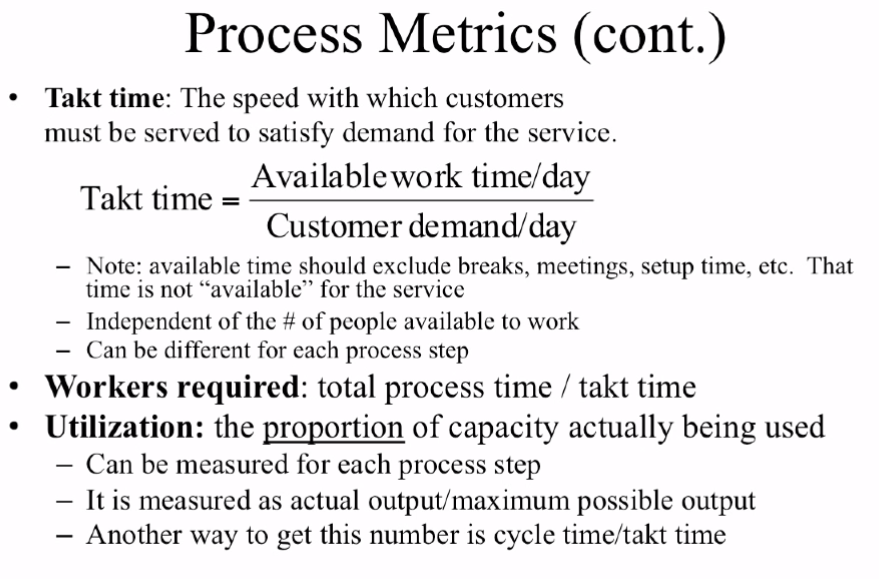

Takt Time

Total Productive Maintenance (TPM)

Value Stream Mapping

Visual Factory

https://www.youtube.com/watch?v=dTkW_nrjiRk

DMAIC - Define, Measure, Analyze, Improve, Control

Define - Create the Project Charter, Interpret the Voice of the Customer, Understand the Current State, Develop Project Communication

Clarify the issue, Understand who is involved, Define the scope, Engage those impacted, Clarify customer expectations

Measure - Select Measures, Plan for Data Collection, Collect Baseline Data

Determine if issue exists, Assess if it's worth addressing, understand the process, focus projects effors, establish the baseline

https://www.youtube.com/watch?v=m50Tzn4x-iU